magnetic separators

the front line for improved product purity and asset protection

protect

Safeguard important upstream assets from damage and repair.

Quality

Improve product purity by removing tramp metal.

efficient

Never stop the process flow to remove contaminants.

Accurate Industries is proud to be partnering with one of the world’s longest standing & most respected names in magnetic separation, DINGS MAGNETICS. For more than 125 years DINGS MAGNETICS has been a leading USA based manufacturer for an extensive range of high quality, high strength magnetic separators for a vast array of industrial applications.

Overhead Stationary Electromagnet & Protector Tramp Metal Detector

Overhead Stationary Electromagnet

dings magnetics

advanced

Dings Flux Control (DFC) for permanent magnets is a unique and market leading design that delivers:

- Stronger magnetism

- Deeper magnetic fields, and

- A more uniform pattern of distributed magnetic field

ding's magnetics

engineered

Each Magnetic Separator is specified per application and custom manufactured in the USA to ensure the correct magnetic separator is supplied every time.

ding's magnetics

built to last

Magnetic Separators from Dings Magnetics are built to withstand the rigors of time and the harshest environments & offer peace of mind with the best equipment warranty in the industry.

- 20 years warranty on coil burnout for electromagnets.

- Lifetime warranty on magnetism for permanent magnets.

Overhead Permanent Self-Cleaning Magnet

industry insight

magnetic separators for mining and quarrying

In mining & quarrying applications ferrous (tramp metal like bucket teeth, etc) needs to be removed to protect valuable assets like conveyors, screens and crushers from damage, costly repairs & downtime. The other benefit of tramp metal removal is enhanced product purity. Accurate Industries offer a full range of Dings Magnetic Separators from stationary Permanent Magnet units through to Self-Cleaning Electromagnet units.

separator types

overhead electromagnetic and permanent magnet separators

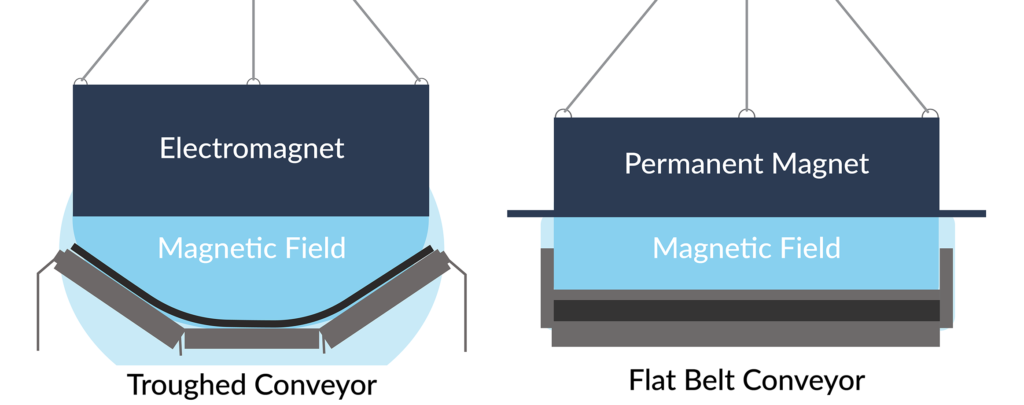

Overhead ELECTROMAGNETIC separators allow greater control over the presence of the magnetic field. By simply cutting the power, ferrous material will be released for rapid cleaning. The deep toroidal shape of the magnetic field produced by an electromagnet can make it the magnet of choice for troughed belt conveyors.

Overhead PERMANENT magnetic separators always have a magnetic field and don’t require any outside energy to produce it. Permanent magnets are more space efficient than electromagnets. This smaller size makes them ideal for use in tight spaces. The constantly active magnetic field, permanent magnet separators require manual cleaning for Stationary models.

magnetic separator unit types

stationary units

If tramp metal is rare in the mining or quarrying environment but intolerable, an overhead stationary magnet can be an optimal choice. The absence of the self cleaning belt allows the magnet face to be closer to the conveyor which reduces the requirements for the magnetic field and overall physical size. Stationary magnetic separators have no moving parts and require minimal service.

Overhead Stationary Permanent Magnet

Overhead Stationary Electromagnet

magnetic separator unit types

self-cleaning units

If tramp metal is prevalent in the mining or quarrying environment, then a self-cleaning model is recommended. A self-cleaning magnet uses a multi-ply rubber belt with one inch vulcanized cleats that travel across the magnet’s face automatically discharging the ferrous contaminants.

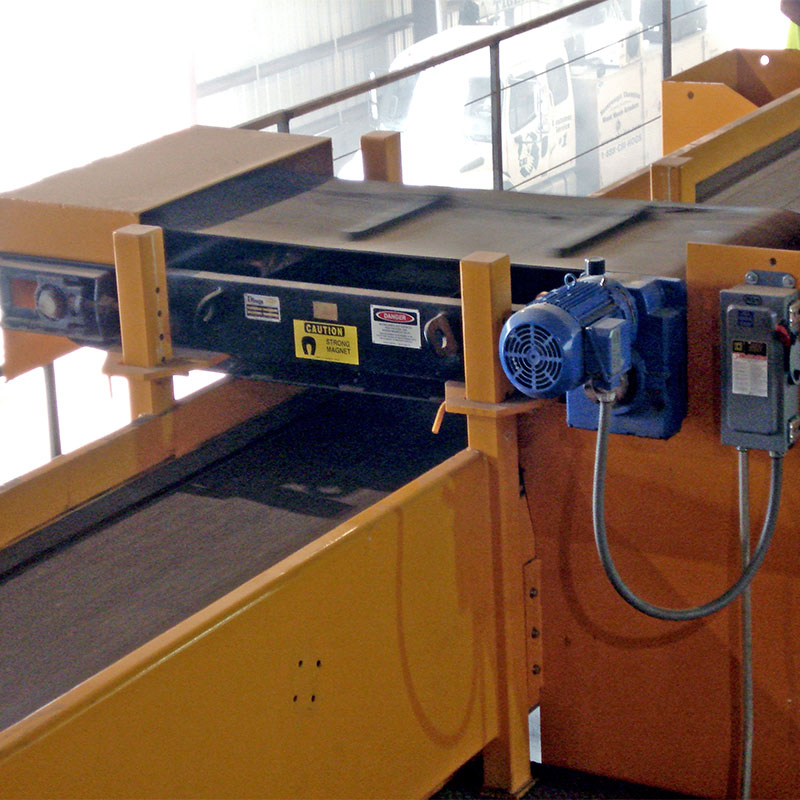

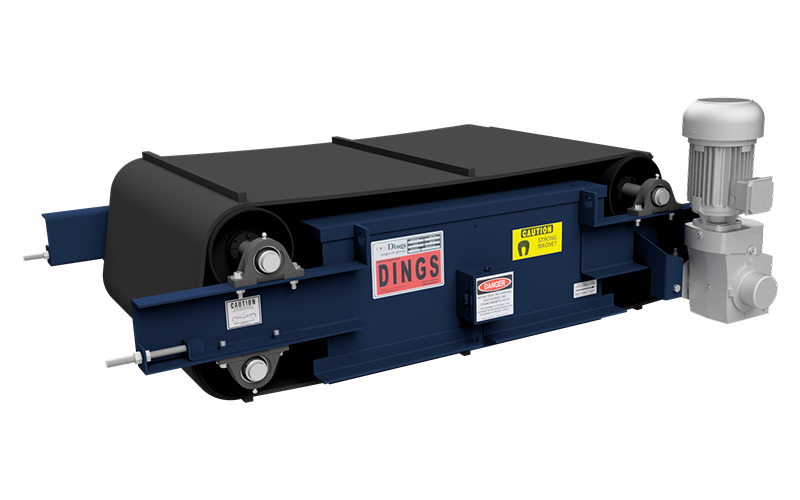

Overhead Self-Cleaning Electromagnet

- 20 Year warranty on coil burnout

- Easy to clean/clear away tramp

- Stainless steel bottom and center wear plate

- Controllable

- Low maintenance

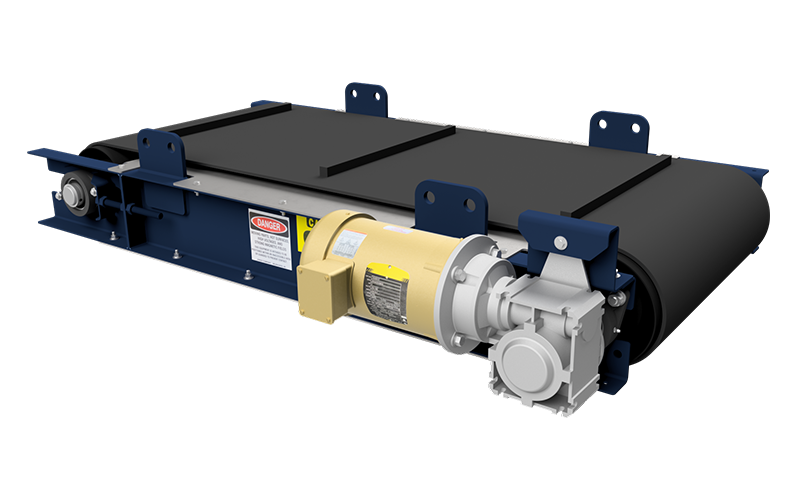

Overhead Self-Cleaning Permanent Magnet

- Lifetime warranty on magnetism

- Most compact size in the industry

- Full stainless steel bottom plate

- Zero power consumption

- Zero maintenance (for stationary models)

magnetic separator unit types

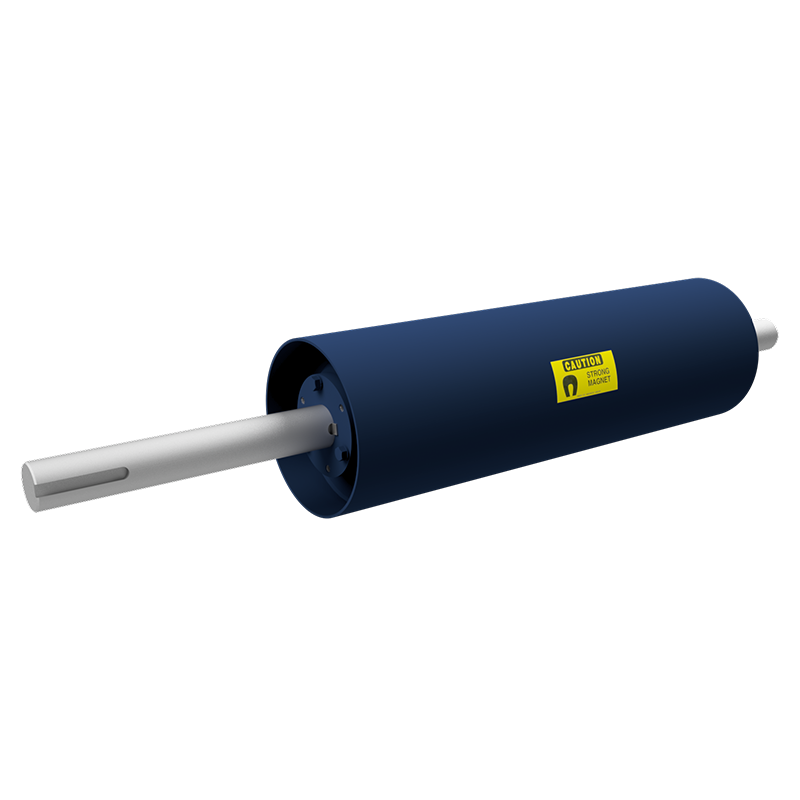

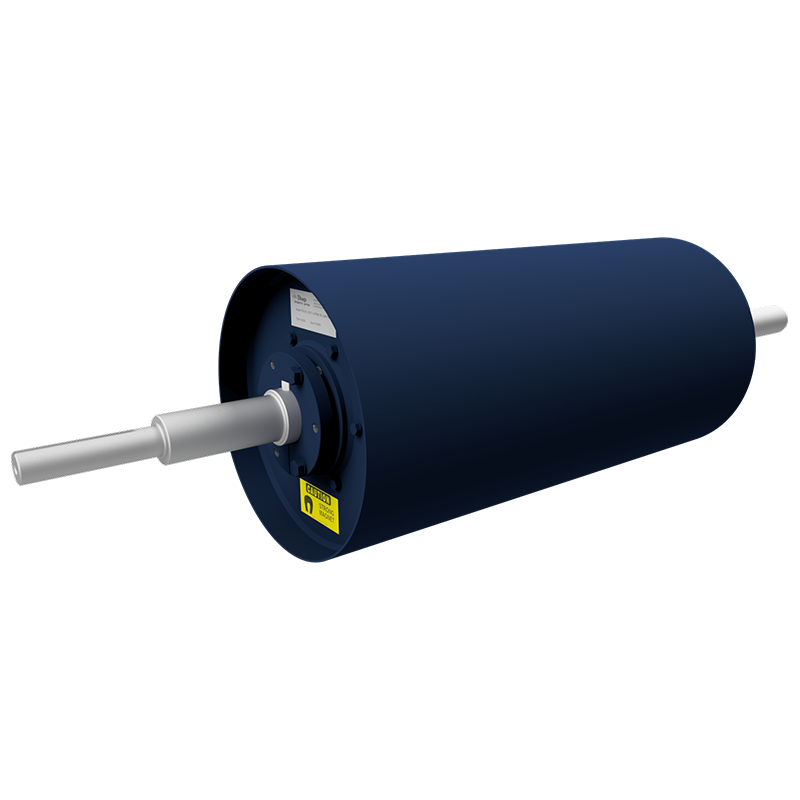

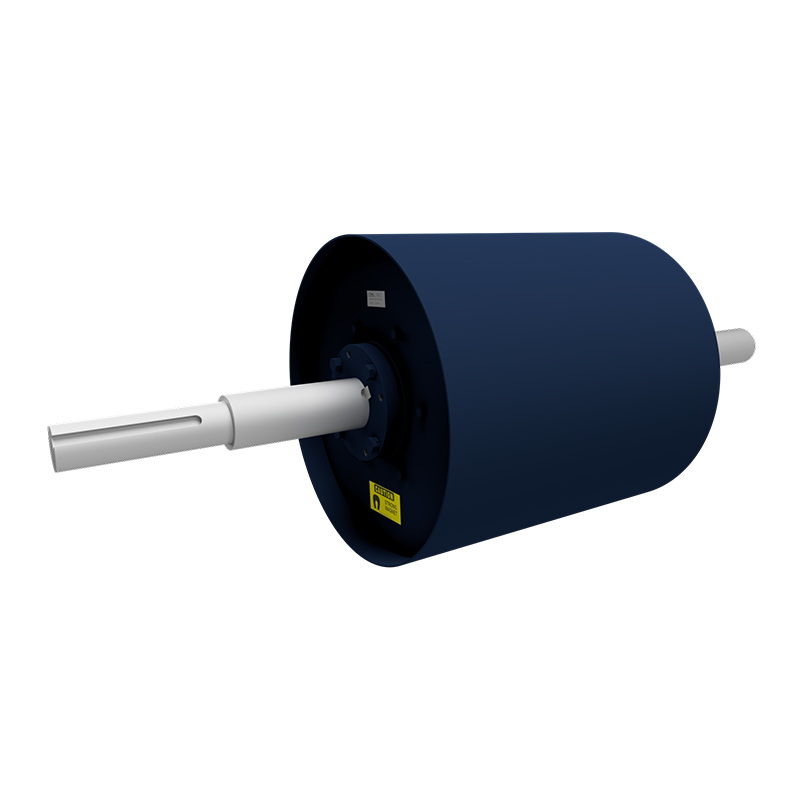

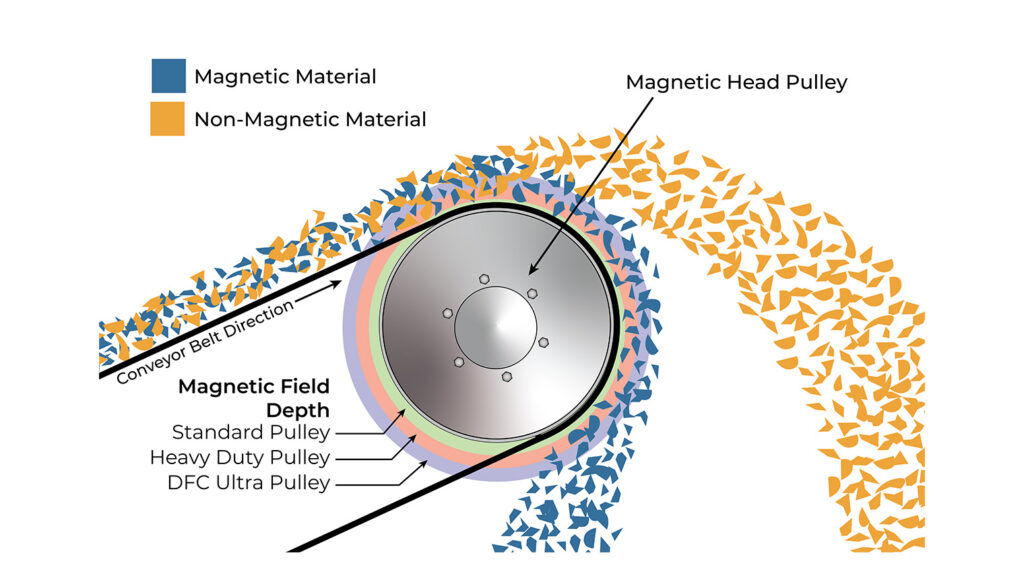

magnetic head pulley separators

Magnetic head pulleys are non-electric, self-cleaning magnetic separators. They operate as head pulleys on conveyors to separate tramp iron and iron impurities from conveyed product and are designed for machinery protection and product purification. As product is discharged from the conveyor, non-magnetic material follows its normal trajectory off the belt while ferrous clings to the magnetic pulley until it is released under the conveyor as the tramp iron leaves the pulley’s magnetic field.

Dings manufactures three different strength series to accommodate varying burden depths and throughput volumes, Dings standard, heavy-duty and DFC Ultra.

Key Magnetic Separator Considerations

how to select the correct magnetic separator

Selecting the right Magnetic Separator for the task can be influenced by a wide number of factors like….

- Target size & type of tramp metal to be removed

- Prevalence of tramp metal in the product stream

- Conveyor width

- Belt depth & troughing angle

- Burden Depth

- Lump size

- Separator orientation

- Separator location

- Location constraints (available room, etc.)

- …and more

To find out more about our extensive range of magnetic separators, download our complete product guide below.

FAQ

Magnetic Separators Frequently Asked Questions

Is a magnetic field dangerous to me?

Magnetic fields can produce dangerously strong forces on iron or steel objects which can cause crushing or impact hazards for persons in the area. Magnetic fields can damage or interfere with pacemakers and other electronic devices. The danger of a particular magnetic field depends on its strength and other characteristics.

What kinds of magnets are the strongest?

Rare earth magnetic material is the strongest type of permanent magnetic material. Rare earth magnets produce the strongest field for a given size of permanent magnet and are mainly used in applications where space is limited. The strength of any type of magnet is based on its size and design. Permanent magnets made with “weaker” magnetic materials can be much stronger than rare earth magnets if they are much larger in size.

What is the difference between a permanent magnet and an electromagnet?

Permanent magnets produce a magnetic field without the need for any external source of power. The permanent magnet’s properties exist when the magnet is magnetized. An electromagnet generates a magnetic field only when an electrical current is applied to it. The magnets on your refrigerator are permanent magnets.

Why is my magnetic separator not as strong as it used to be?

Permanent magnetic separators are most commonly weakened by extreme temperatures. Electromagnetic separators most often lose strength due to less power being supplied to the magnet or reduced effectiveness of the magnet’s cooling system. In either magnetic separator type, the introduction of ferrous structure or components around the magnet can also lead to reduced performance.

get in touch with us

and let us deliver best in class outcomes to you

Core to our operation is developing relationships with our customers so we can understand their problems, concerns, and goals, to ensure we deliver the best outcomes possible. We provide accurate, reliable, and honest service and information to our customers and ensure the correct equipment and solutions are provided every time, without fail.