Tramp Metal Detectors

Protect your assets

with the last line of defence

Tramp Metal Detectors perform a vital role in most processing plants by preventing harmful objects such as tramp metal from being conveyed upstream and potentially damaging critical and expensive infrastructure. Accurate Industries is proud to be partnered with the USA based ADS Detection range of equipment. ADS Detection boast more than 30 years of experience in the manufacture of Tramp Metal Detector equipment & have a global install base in the mining and quarrying industries. ADS Detection SurroundScan Tramp Metal Detectors perform at the highest levels & are built to last.

Protect

Safeguard important upstream assets from damage & repair.

De-Risk

Avoid unnecessary downtime.

Confidence

The ultimate ‘back up’ system for asset protection.

key element 1

robust

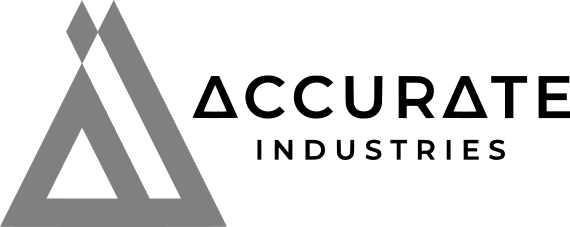

Unlike others on the market, the SurroundScan series of Tramp Metal Detectors by ADS Detection are made to withstand the most punishing site conditions. This heavy armour protects sensitive electronics and ensures maximum uptime.

key element 2

Intuitive

Each SurroundScan Tramp Metal Detector is fitted with a simple to navigate & intuitive touchscreen user interface located on the detector frame. Automatic product learning, product monitoring & automatic balancing are all standard features and enable rapid setup & deployment.

key element 3

Fit for Purpose

From the Range of sensitivity levels, aperture sizes, accessories & heavy-duty steel construction, through to the patented enhancement technology & software, the SurroundScan Tramp Metal Detectors deliver the best possible performance for heavy industry.

Metal Detectors

Surroundscan Protector Series

Available in 3 models with 2 ranges of aperture size and 2 sensitivity levels, the protector series of Tramp Metal Detectors has a model to suit the most challenging applications.

| Protector LP | Protector HD | Protector HD Ultra | |

|---|---|---|---|

| Aperture Size | |||

| Sensitivity | Standard | Standard | 2x Standard |

| Detect Increment | 10mm | 10mm | 5mm |

Protector LP

Protector HD

Protector HD Ultra

AccuLearn Technology

Setting up products with the AccuLearn Technology is easy and efficient. In as few as 1-2 minutes, the metal detector will learn your product's signature, allowing clean product to pass through while accurately identifying and rejecting products that have metal contamination.

Product Monitor

With Product Monitor, you get real time signal values for your product and the tramp metal that must be detected.

Patented Auto Balance

Advanced Detection Systems' auto-balance software maintains perfect coil balance and optimum performance, eliminating the cost of a service technician plant visit to re-balance the metal detector.

Patented Vibration Technology

ProScan vibration technology monitors interference created by vibration and automatically compensates for the effect, thus enhancing reliability and sensitivity.

metal detector add-ons

optional accessories

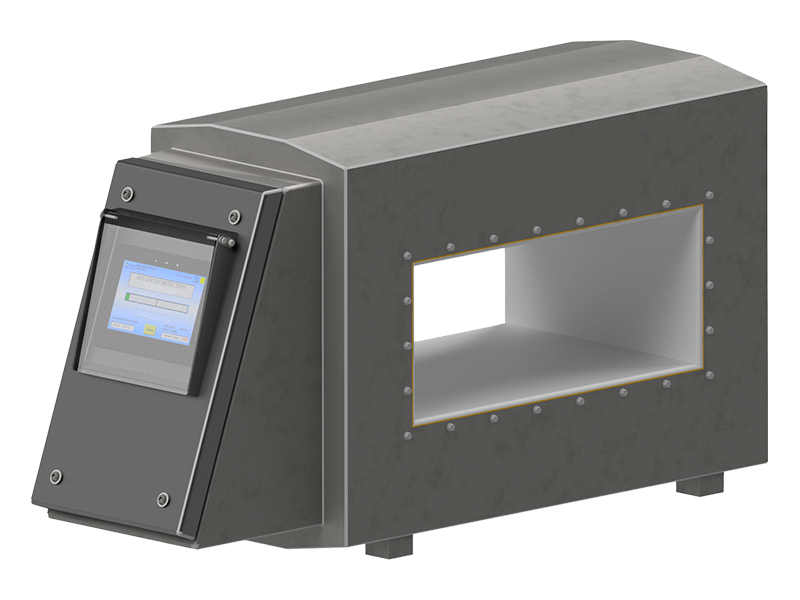

Metal Marker

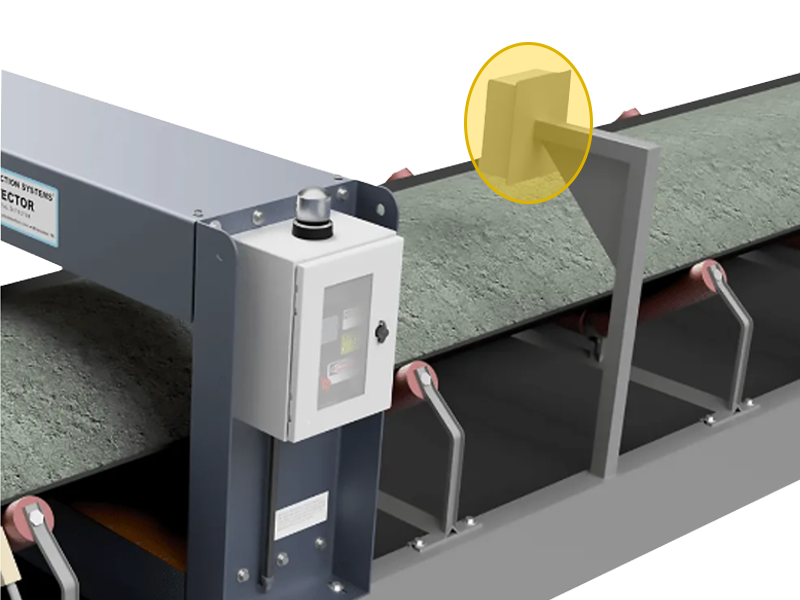

Splice Sensor

The metal marker is an optional accessory used to mark on the belt when tramp metal has been detected in your production stream.

The splice sensor is an optional accessory used to accommodate ferrous belt splice and repairs.

Metal Detectors

surroundscan defender III

Ideal for processing applications, the Defender III can restore product purity and protect valuable assets from the smallest metallic objects.

| Component | Defender III |

|---|---|

| Aperture | |

| Sensitivity | Highest |

| Detect Increment | 2.5mm |

AccuLearn Technology

Setting up products with the AccuLearn Technology is easy and efficient. In as few as 1-2 minutes, the metal detector will learn your product's signature, allowing clean product to pass through while accurately identifying and rejecting products that have metal contamination.

Product Monitor

With Product Monitor, you get real time signal values for your product and the tramp metal that must be detected.

Patented Auto Balance

Advanced Detection Systems' auto-balance software maintains perfect coil balance and optimum performance, eliminating the cost of a service technician plant visit to re-balance the metal detector.

tramp metal detector considerations

how to select the correct tramp metal detector

Selecting the right Tramp Metal Detector for the task can be influenced by a wide number of factors like….

- Target size & type of tramp metal to be detected

- Prevalence of tramp metal in the product stream

- Conveyor width

- Belt depth & troughing angle

- Burden Depth

- Lump size

- Detector location

- Location constraints (available room etc)

- & more

Our helpful experts can assist in selecting the best equipment to provide the best outcome.

FAQ

Tramp Metal Detectors Frequently Asked Questions

Why do I need a metal detector?

There are two reasons. The first is protection of your expensive processing equipment. The second is to protect the integrity of your product. One small piece of metal can be devastating to your company’s reputation and equipment if found in a product.

Where should I put the metal detector?

If you are trying to protect your industrial processing or manufacturing equipment, then it should be placed as close to the infeed section as possible while still allowing ample space to stop before metal can enter. If you want to protect your final product, then the metal detector should be located as close to the end of the production line as possible — after the product has been packed.

What factors influence sensitivity?

Product effect, size, shape, type, orientation of metal contaminants, the size of the opening of the metal detector, as well as the environment of operation that the metal detector occupies can all affect the metal detection system’s sensitivity.

How do I choose a metal detector?

Make sure that the metal detector is appropriate for your unique application, the aperture size is appropriate for the various products that will be tested and that the detector is in the right location. Our experts can help you choose which metal detector is appropriate for your needs.

get in touch with us

and let us deliver best in class outcomes to you

Core to our operation is developing relationships with our customers so we can understand their problems, concerns, and goals, to ensure we deliver the best outcomes possible. We provide accurate, reliable, and honest service and information to our customers and ensure the correct equipment and solutions are provided every time, without fail.