Before we get started, please note that this is by no means an exhaustive list of component types and models (we will leave that for the technical documentation), but rather, this is a brief look into some of the industry specific terms that have a common functional meaning and one commonly used but very misunderstood term.

What are the typical Belt Weigher synonyms?

The typical belt weigher synonyms, used ubiquitously and often interchangeably are:

- Belt Weigher

- Weightometer

- Belt Scale

- Conveyor Scale

Firstly, let’s start off with the device name. Like a lot of devices, Belt Weighers can be referred to by several different names which all mean the same thing. Some of the terms are more popular in certain geographical regions whereas other terms are preferred in certain industries. Either way, all the terms refer to the same product.

More Belt Weigher synonyms

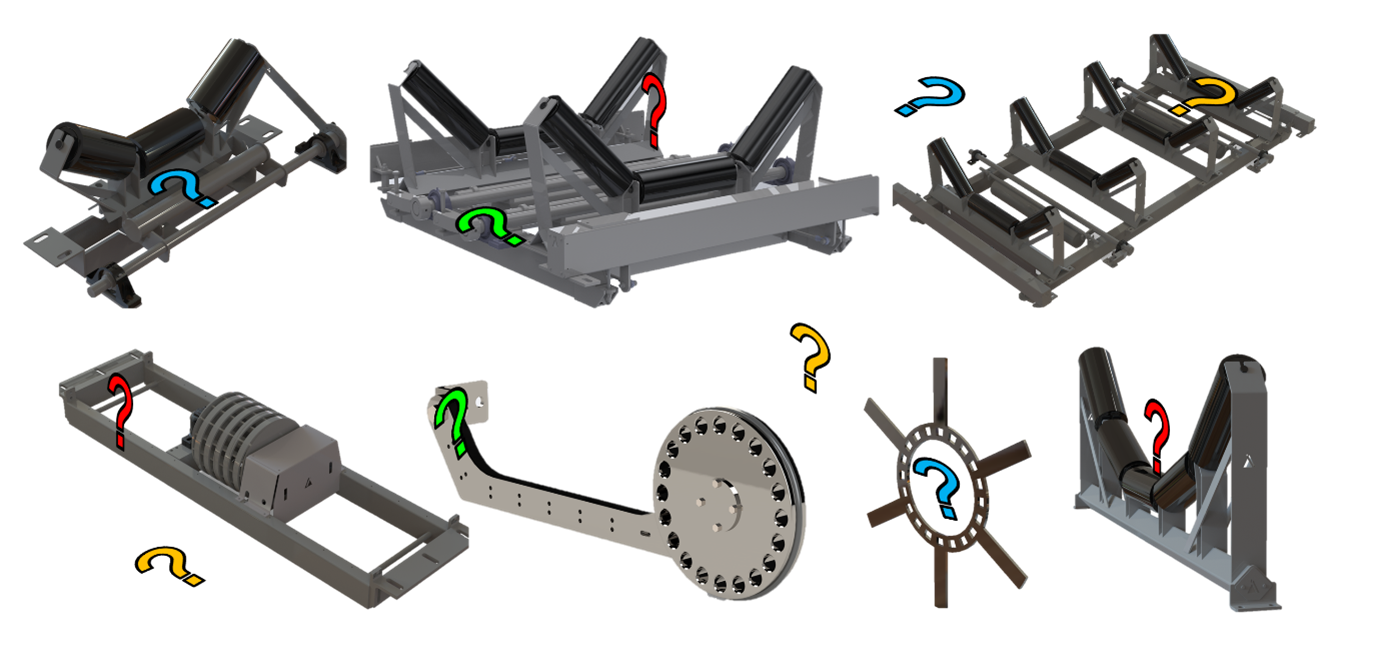

Just like the overarching device itself, some of the primary components of belt weigher systems are also referred to by multiple names that all essentially perform the same function despite varying in physical appearance, construction or technology. Below is a brief rundown:

WEIGH CELL = LOAD CELL = SHEAR BEAM = S TYPE = LVDT

While these devices are technically very different from each other, they all perform the same function, and they all belong to a wider group of instruments known as transducers. For weighing applications, a transducer converts a mechanical movement (i.e. weight being applied) into an electrical/electronic output/signal for further processing by other devices.

SPEED SENSOR = TACHOMETER = TACHO WHEEL = PROX WHEEL

Like weigh cells, Speed Sensors can also vary greatly in physical appearance, construction, and eventual placement. They can be referred to by several different names. These names are usually related to the type of deployment or application. Speed sensors also belong to the Transducer family of instruments as they convert the mechanical movement (of the belt) into an electrical/electronic output/signal for further processing by another device.

BELT SPLICE = BELT CLIP = BELT JOIN

This term is a little more obvious and only really comes up in Belt Weigher conversations because the location at which two sections of conveyor belt are joined together and the quality and physical characteristics of that join can greatly influence the performance and accuracy of the Belt Weigher system. These terms often appear on Belt Weigher test reports.

INTEGRATOR = CONTROLLER = INDICATOR

For belt Weighers, these terms refer to the electronic unit that received all the signals from the transducers in the field (Weigh Cells and Speed Sensors) and converts them into usable information like rate per hour and total tonnage. Strictly speaking these units should be referred to as Integrators when considering Belt Weigher systems.

Accuracy vs. Error

Belt weigher systems are often defined by the accuracy that they can deliver, and this accuracy is often expressed as a percentage. Belt weigher systems are typically advertised and promoted as being able to deliver accuracies of +/- 5%, 2%, 1%,0.5%, or 0.25% depending upon the type/model and some other characteristics. These numbers are terrifyingly low if they related to actual measurement accuracy. Who would want a measurement device that is only accurate within 1%? The stated “Accuracy” of a Belt Weigher actually refers to the ERROR than can be reasonably expected when considering the final measurement results.

Conceptually speaking, ACCURACY & ERROR are miles apart. Accuracy suggests confidence & reliability whereas Error suggest doubt & uncertainty. So, for Belt Weigher systems, a lower stated “Accuracy” will in fact deliver a lower “Error”. (a bit like golf….the lower the score, the better the result).

So, when you are considering what accuracy class you should select for your next Belt Weigher, perhaps you should also consider, what is the level of doubt or uncertainty is my business willing to accept? Does that level of doubt or uncertainty cascade through upstream processes & potentially induce ever greater levels of error?