BELT RADAR AND SAFETY PRODUCTS

PRECISION MONITORING. MAXIMUM SAFETY. LOCAL EXPERTISE.

ALL FROM A SINGLE AGENT

Protect your conveyors, maximise uptime, and improve accuracy with world-leading radar monitoring and safety systems – all fully supported, installed, and maintained onsite by Accurate Industries.

THE CHALLENGE WE SOLVE

Unplanned conveyor stoppages create heavy cost burdens from lost throughput, urgent maintenance, and labor inefficiency. Our solutions help prevent:

- Guesswork in material flow and belt loading

- Belt misalignment, wear, spillage, and damage

- Undetected belt rips and catastrophic failures

- Speed fluctuations and slip

- Heavy reliance on manual inspections

OUR PROCESS

How we achieve best in class outcomes

Consult & Assess

Understanding your operational needs and risks

Design Solutions

Choose from leading radar and safety products

Install & Integrate

Deploy onsite for seamless fit/function

Calibrate & Commission

Assure optimal performance and accuracy

Support & Maintain

Service, training, and upgrades as required

BELT RADAR AND SAFETY

TECHNOLOGY WE DELIVER

We’re committed to providing the right solutions for your unique operational requirements.

RADAR PRECISION FOR EVERY BELT

INDURAD iBELT RANGE

The iBelt range from Indurad is the next generation in conveyor belt monitoring, enhancing conveyor operations with high-speed 2D radar scanning for accurate volume flow measurement, capturing cross-sectional views, and providing height and material distribution insights.

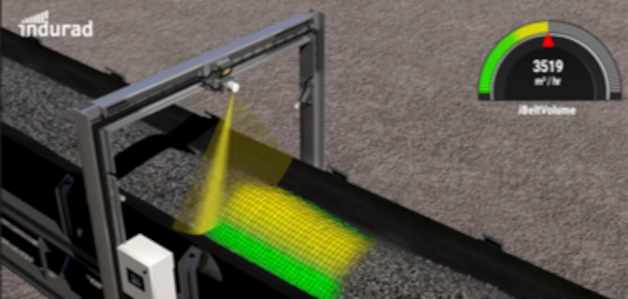

iBeltVOLUME

Real-time load measurement. 2D radar scanning for accurate, real-time measurement of belt load cross-section, unaffected by dust, fog, steam, or snow, with up to 99% accuracy.

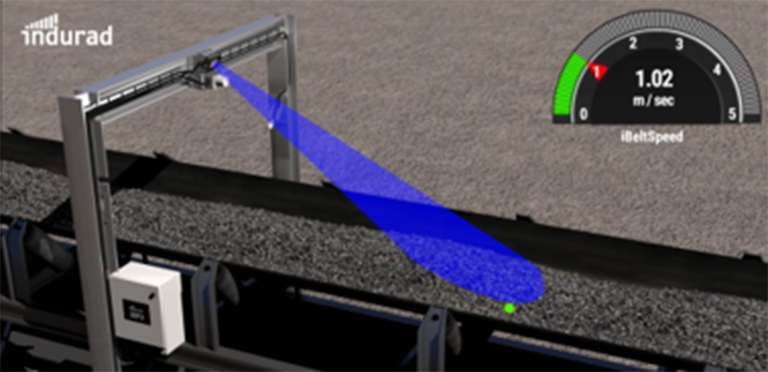

iBeltSPEED

Precise speed and slip monitoring. Contactless, accurate speed measurement that instantly detects slip, removing the need for recalibration.

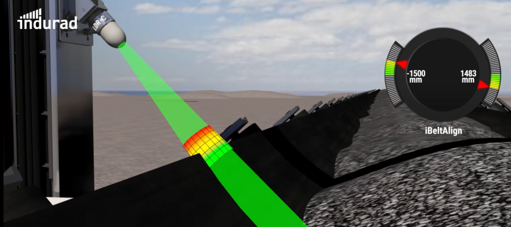

iBeltALIGN

Proactive misalignment detection, even in dust, fog, and vibration.

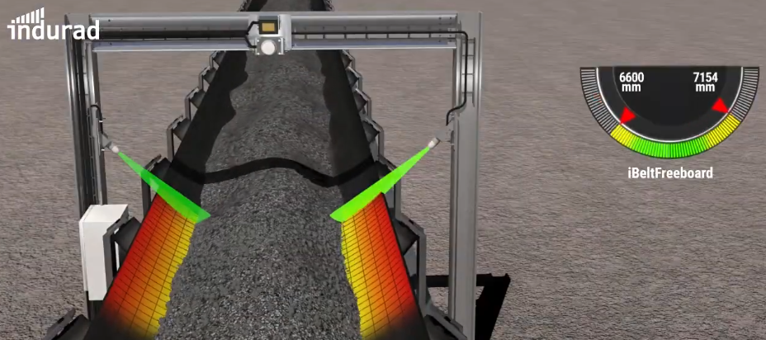

iBeltFREEBOARD

Monitors material position and safeguards belt life.

COMPLETE CONVEYOR PROTECTION

INELCO SMART SERIES

The Inelco Smart Series delivers rugged, reliable conveyor protection systems that keep operations safe, efficient, and running without costly interruptions. Some of our most requested Inelco Smart Series products include:

RipPrevent’s advanced AI system monitors electrical, massflow, speed, and conveyor data 50x/sec. It detects anomalies and warns before actual rips, integrating directly with your PLC for automatic shutdown.

BRC1 Belt Rip Detector

Mechanical, IP67-rated, stainless steel/brass, maintenance-free.

BM2 Belt Misalignment Switch

Detects excessive drift, activates stops/alarms.

BT2000 Belt Tear & Spillage Detector

Basket assembly, triggers sensor on spillage for early repair.

RBS Return Belt Spillage & Tear Detector

Monitors return belt; tilting catch plate activates alerts.

Essential Safety Devices

Emergency pull wires, drift/chute/material sensors—engineered for reliability.

AI-POWERED BELT TEAR PREVENTION BY SHG CONVEYOR CONTROL

RIPPREVENT

RipPrevent is an AI-driven conveyor belt monitoring system that analyses real-time operational data to detect and prevent belt rips before they occur – without the need for belt mounted sensors. This approach offers predictive protection, lower maintenance costs, and easy integration with existing plant control systems.

RipPrevent’s advanced AI system monitors electrical, massflow, speed, and conveyor data 50x/sec. It detects anomalies and warns before actual rips, integrating directly with your PLC for automatic shutdown.

NO SENSORS INSIDE BELT

This means no wear or belt modification.

HIGH COMPATABILITY

Works on all belt types and cover ratios, 600mm-6000mm width, up to 12m/s speed.

LIVE ANALYTICS

Dashboard for live data, rip indicators, anomaly/event tracking, and uptime/downtime logs.

FAQ

Belt Radar & Safety Frequently Asked Questions

Are radars safe to humans?

Yes, Belt Radar is completely safe for humans. The radar sensors are fully compliant with strict international safety standards and directives, such as the EU Directive for Protection against EM fields (2013/35/EU) and industry standards like DIN EN 50413 and EN 50364, which are designed to limit human exposure to electromagnetic fields. The radiofrequency (RF) emission levels from Belt Radar are well below everyday exposures—comparable to or often lower than common wireless devices like mobile phones and WiFi. Comprehensive certification and compliance documents are available on request; our technical staff can provide further details to meet your site’s requirements.

Are radars affected by dust?

No – one of the main advantages of Belt Radar’s advanced radar technology is that it is not affected by dust, unlike some laser-based volumetric systems. The system is engineered to function reliably in extreme industrial environments with dust, rain, vibration, or temperature swings. This ensures precise, maintenance-free bulk measurement even where visibility is severely limited. If you want examples from operations similar to yours or have specific conditions in mind, our support team is ready to advise on the best solution for your needs.

When would I use a radar for belt volume rather than a traditional belt weigher?

Radar-based belt volume measurement is ideal for challenging conveyor applications—such as light loading, areas where there’s not enough space for a full belt weigher, or in zones with high tension or curves where belt weighers are difficult to install or maintain. In some applications, combining radar volume measurement with a belt weigher enables live calculation of material density, providing a powerful tool for process optimization and reconciliation. Since every conveyor is unique, reach out to our technical specialists, who can review your requirements and help select the perfect solution for your site.

get in touch with us

and let us deliver best in class outcomes to you

Core to our operation is developing relationships with our customers so we can understand their problems, concerns, and goals, to ensure we deliver the best outcomes possible. We provide accurate, reliable, and honest service and information to our customers and ensure the correct equipment and solutions are provided every time, without fail.