belt weighers

optimise your conveyor belt operations

with precision measurement

Precise

The highest possible accuracy for the equipment and conditions.

Robust

Made for the environment, our belt weighers are built to last.

Flexible

Flexible designs to meet all requirements and conveyor types.

Belt weighers (also known as conveyor belt scales) are precision weighing and measurement machines that provide your conveyor belt operations the much-needed intelligence to operate at peak performance.

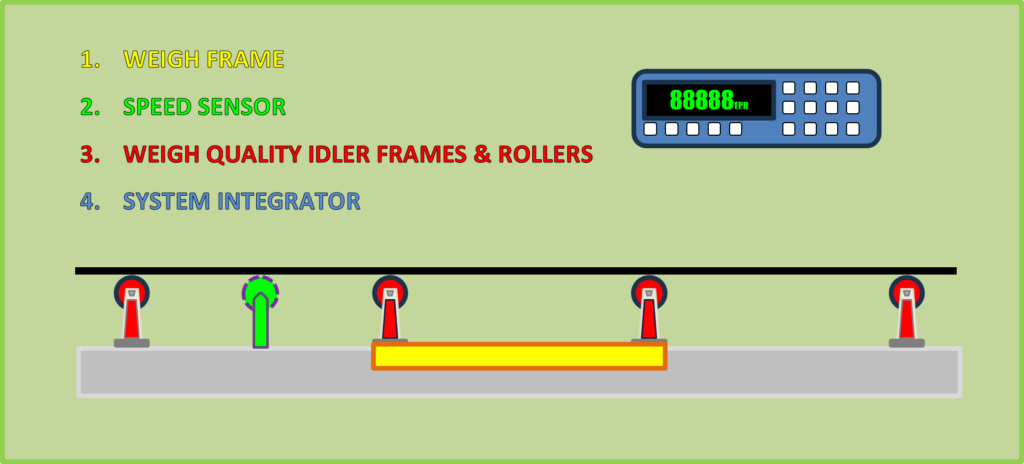

belt weigher systems

key elements

Belt weighers measure the weight and speed of product on a belt to then calculate rates and totals. To achieve this outcome there are four key elements to all belt weigher systems that we’ve outlined below.

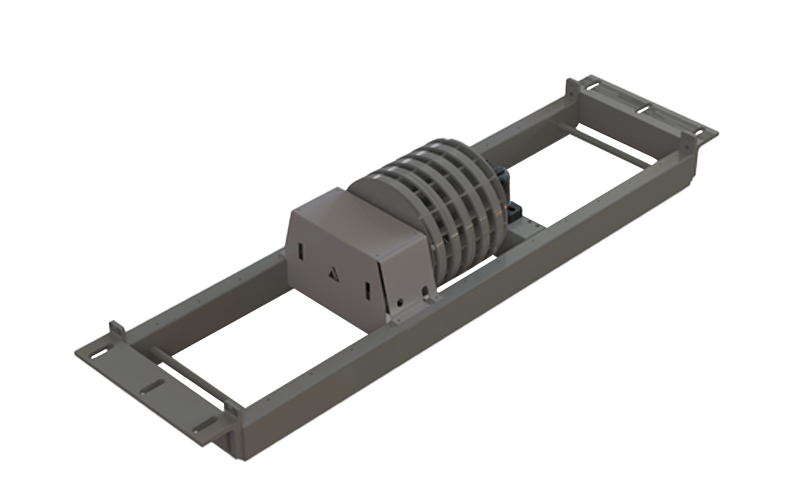

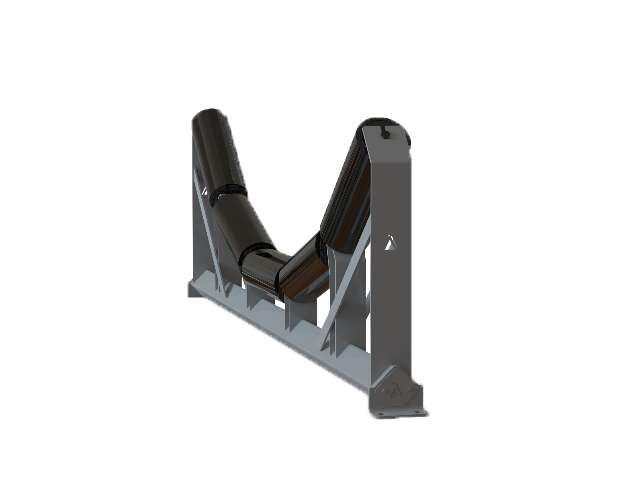

weigh frames

Attached to the conveyor stringers, the weigh frame is a structure usually made of steel that contains weight sensitive transducers and performs the weight measurement function of the system.

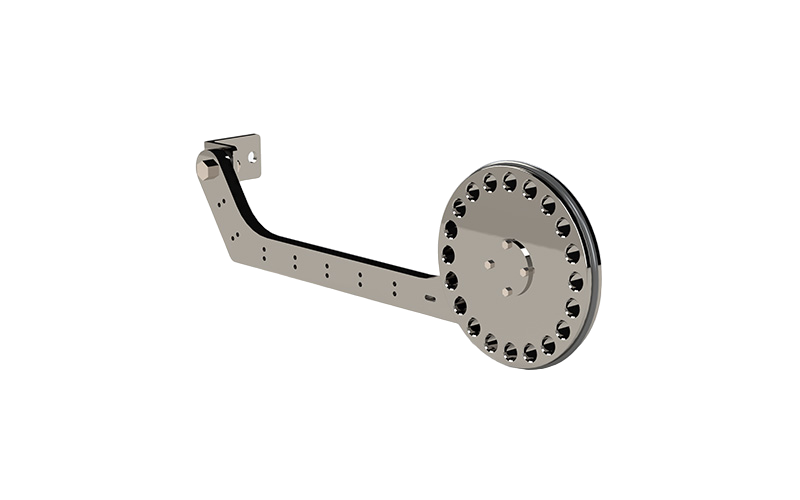

speed sensors

Typically, a rotary encoder type of device, Speed Sensors measure the speed of the conveyor belt & are available in a variety of types and styles to suit various applications.

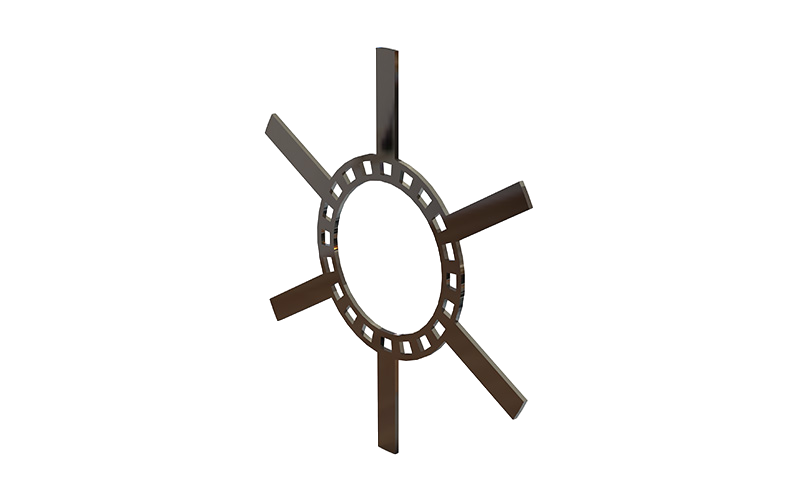

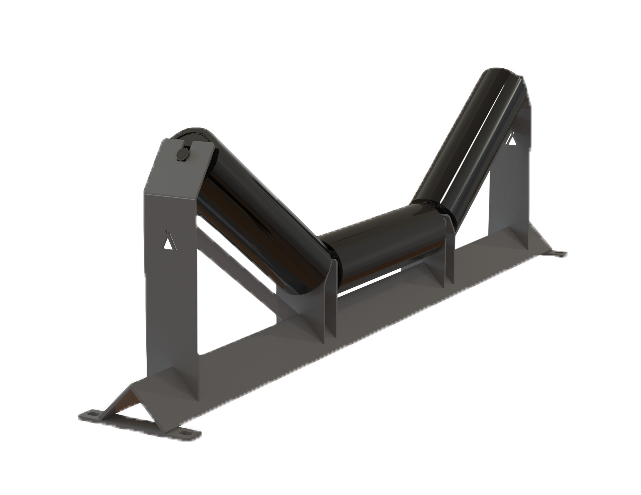

weigh quality idlers & rollers

Weigh quality Idler Frames & Rollers form the critical & sensitive physical connection between the weighing system & the conveyor belt.

integrators

The Integrator performs the final and essential role of combining the weight and speed signals and converting those signals into rates and totals on a display as well as suppling live output data to the site control system.

key elements

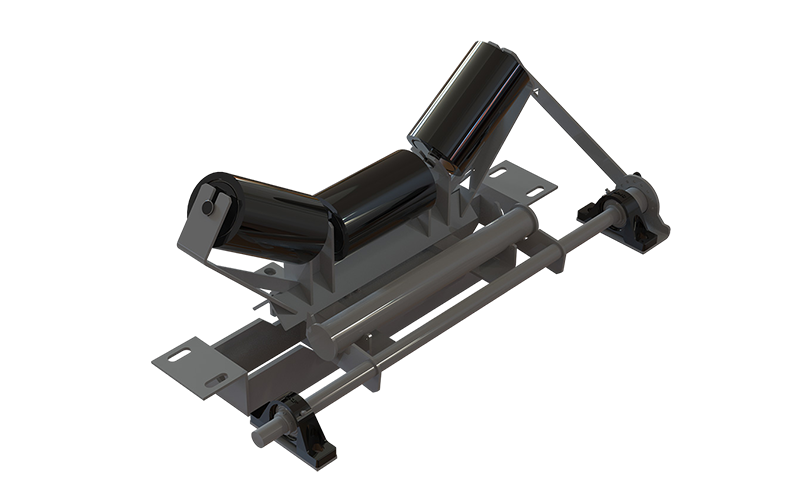

weigh frames

Accurate industries offers a comprehensive range of Weigh Frame sizes, types and accuracy classes to suit a wide variety of applications & requirements. Manufactured in house to our own industry leading design, Accurate Industries Weigh Frames are fabricated in mild steel with a hot dipped galvanized finish for durability as a standard and can be supplied in stainless steel with a bead blast finish for challenging environments as an option.

| Component | Compact | Multi |

|---|---|---|

| Belt Widths | 500mm to 1500mm | 450mm to 2200mm |

| Idler Spacing | 500mm to 1500mm | 900mm to 1500mm |

| # of Idlers With Rollers | 1 x Standard | 2, 3 or 4 weigh quality idler frames with weigh quality rollers. |

| Accuracy | From +/- 1% | From +/- 0.25% |

| Construction | Stainless Steel | Heavy Duty Mild Steel (Option: Stainless Steel) |

| Finish | Bead Blast | Hot Dipped Galvanised (Option: Bead Blasted for Stainless Steel) |

| # Load Cells | 1 | 4 connected in parallel |

| Load Cell Rating | OIML R-60, 150% overload | OIML R-60, 150% overload |

| Stored in Place Calibration Weights | – | 2, 3, or 4 |

Please note: System accuracy is dependent on speed, environmental conditions, and installation location. Custom widths are available.

key elements

speed sensors

Precise & consistent speed measurement is essential for Belt Weigher System accuracy. Conveyor characteristics vary greatly from one to another, and to meet that variability Accurate Industries provides a range of robust & industry proven speed sensor options to deliver the best possible speed measurement. Accurate Industries Speed Sensors are also suitable for use with Tramp Metal Detectors, Continuous Belt Speed Monitoring, & Belt Under Speed measurement.

| Component | Spiral Cage | Trailing Arm | Drum Mounted |

|---|---|---|---|

| Belt Widths | 600mm to 2400mm | N/A | N/A |

| Belt Speeds | 0.1 m/s up to 5 m/s | 0.1m/s up to 3 m/s | N/A |

| Output | Up to 25 pulses/min (option: additional outputs) | Up to 33 pulses/m | Dependent on size of drum |

| Construction | Heavy Duty Mild Steel (option: Stainless Steel) | Heavy Duty Mild Steel (option: Stainless Steel) | Heavy Duty Mild Steel |

| Finish | Hot Dipped Galvanised (option: Bead Blast for Stainless Steel) | Adonized (Bead Blast for Stainless Steel) | Zinc |

| Bearings | Standard (option: Heavy Duty) | Standard | Standard |

| Sensors | 3 wire NPN (option: 2 Wire, Namur, or more) | 3 wire NPN (option: 2 Wire, Namur, or more) | 3 wire NPN (option: 2 Wire, Namur, or more) |

- Self-cleaning

- Robust, low wear, low maintenance and high reliability.

- Can be mounted close to the belt weigher reducing installation costs and improving system accuracy.

- Simple installation

- Can be mounted close to the belt weigher

- Simple installation

- Easy replacement

key elements

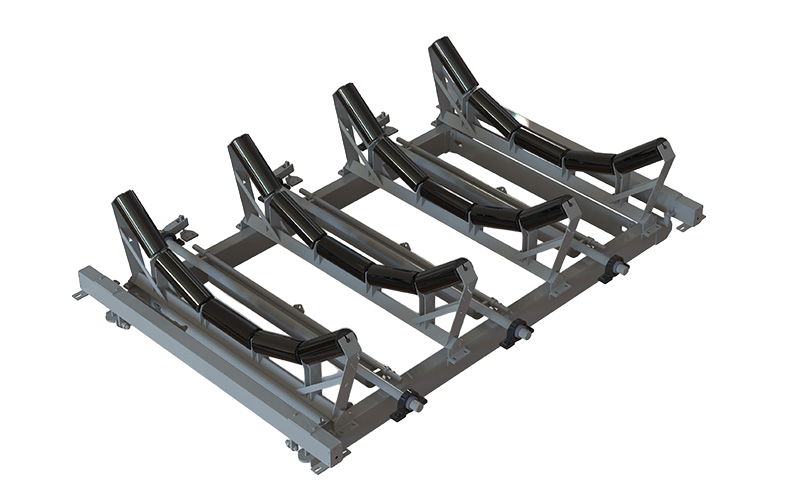

weigh quality idler frames and rollers

The use of Weigh Quality Idler Frames fitted with Weigh Quality Rollers is essential for overall system accuracy. Accurate Industries manufacture Weigh Quality Idler Frames in house to our own stringent design to ensure durability and correct weight distribution to the Weigh Frame. All Weigh Quality Idler Frames supplied by Accurate Industries are fitted with Weigh Quality Rollers that are machined & balanced to the required ISO standards.

| Component | Weigh Quality Idler Frames & Rollers |

|---|---|

| Belt Widths | 600mm to 2400mm |

| # Rollers/Idler | 1, 3, or 5. |

| Roller Lengths | Per application |

| Roller Case Material | Heavy Duty Mild Steel (option: Stainless Steel) |

| Roller Case Thickness | Per application |

| Bearings | Heavy Duty |

Note: Custom widths are available.

key elements

integrators

Whatever the application, Accurate Industries has an integrator to meet the requirements. Accurate Industries represent some of the worlds leading and industry respected brands EMC ModWeigh & Schenck Process Intecont Tersus to process measurement signals and deliver critical material flow data to operators and plant control systems.

key belt weigher considerations

how to select the correct belt weigher system

Selecting the right Belt Weigher System for the task can be influenced by a wide number of factors like….

- Conveyor Width

- Conveyor Speed

- Conveyor Incline Angle

- Conveyor Tensioning System

- Idler Spacing & Height

- Number of Rollers per Idler

- Product Properties (kg/m)

- Intended Weigh Frame Location

- Integrator Location

- and more…

FAQ

Belt Weigher Frequently Asked Questions

What applications can I use a belt weigher for?

Product Inventory/Stockpile Measurement

Plant Balance & Efficiency

Train/Truck/Ship Load Out

Rate/Flow Control

What makes the best belt weigher system?

Proper installation of the appropriate hardware to meet the specification

Proper location placement of all hardware to achieve the best possible results

Proper and consistent belt tension, especially over the weigh frame

Proper and regular housekeeping of the weighing and speed sensing components

What is the difference between belt weigher accuracy and system accuracy?

Belt Weigher Accuracy (which is often quoted at figures of 0.1% up to 5%) refers to the maximum expected error of the weighing and speed sensing components as an isolated device in perfect operating conditions. System accuracy refers to the maximum expected error of the measured system results post installation into a conveyor line. Generally, the maximum expected error for an installed system is higher once influences such as belt tension, structural rigidity of the conveyor, operating climate and conditions and more have been factored.

get in touch with us

and let us deliver best in class outcomes to you

Core to our operation is developing relationships with our customers so we can understand their problems, concerns, and goals, to ensure we deliver the best outcomes possible. We provide accurate, reliable, and honest service and information to our customers and ensure the correct equipment and solutions are provided every time, without fail.